-

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Ever wondered, how some stuff moves from one place to another without coming in contact with each other. If you have, then now I am going to introduce something called magnetic coupling - your new best friend and mine. This is a unique use of magnets to transport objects without them making any physical contact. This algorithm exists in industrial facilities such as factories and it contains various advantages which describe that this is a brilliant remedy for the sake of implementation. This post is dedicated to what a magnetic coupling in, its advantages and how you can find one that suits your requirement.

Magnetic coupling is possible due to a phenomenon known as Magnetism. Magnets have two poles, North Pole and South pole. This poles draw to one another, which is why they pull together so well. Like a pair of magnets, the closer they get to one another; more strongly hold together and equally harder it is also to pull them apart. This force which pulls them together to stick is known as Magnetic Attraction. This force is used to transport things with no direct contact from one place to another by magnetic coupling.

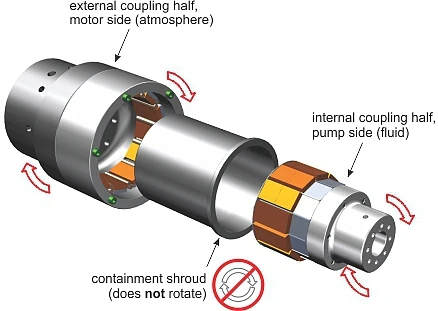

A conventional magnetic coupling system consists of two main components: A drive and a driven magnet. The drive magnet is one that spins around and attaches to a motor. The driven magnet is attached to a shaft that resides on the other side of this area or small gap. As the drive is turned, which changes activates its permanent magnet so a magnetic field now moves across that gap effectively making it spin also. In this manner the driven magnet can be moved by the drive magnet and not in contact with it ever

Effectively Less MaintenanceMagnetic coupling generally has an extremely low maintenance burden. The drive magnet and driven both magnets are not touching with each other, so there is no wear breakering and also the being of Drive or Driven Magnets would have been damaged. It means there is less maintenance, and you do not have to oil or service the system all that much. It is an efficient option in the end as it saves you money and time.

There are a few very important considerations to be had when you end up deciding on the type of magnetic coupling that will work best for your needs. To begin with, you have to understand how much force or torque (as it is rightly referred) that you will require. Such details will be helpful to opt the coupling size according your requirements. The second most important point to consider is how fast the coupling will rotate. Rotational speed will give you an idea of how strong the magnetic field has to be for it work properly.

Also, consider the liquid or fluid being conveyed After all, there are a few types of liquids that can do an incredible amount of damage so you want to make sure the coupling is able to stand up to those potential issues. Another consideration is the temperature Coupling will need to resist breaking down from high heat: In an environment where temperatures can get too hot, your coupling must be able to endure those high temps without falling apart. Lastly, account for the entire size and shape of your system so to make sure that coupling fits accordingly.

While magnetic drive-systems don't require much maintenance, there are a few things we should keep an eye on. It is important to properly align the drive magnet and driven magnets. If not, the system would not work properly. And also the level of magnetic field. If it is too low, the system will not work properly. Lastly, look out for any leaks that can harm the system and contaminate whatever product is being moved.

Magland puts premium technological innovation works Magnetic coupling academic research institutions stay top developments magnetism. ensures innovative magnet assemblies created meet unique needs customers.

Magland committed strict quality control throughout production process. initial screening raw materials final inspection product. Additionally, all products undergo extensive testing compliant international Magnetic coupling SGS, REACH, RoHS, PAH, CE making sure products meet clients' environmental technical requirements.

Magland huge workshop spans 40,000 square metres than 300 pieces top-of-the-line manufacturing equipment, includes robotics well as Magnetic coupling. technology allows accurate efficient manufacturing procedures assure superior product quality.

Leveraging magnetic circuit simulation software, Magland provides customized services meet clients particular Magnetic coupling. Magland specializes customized magnetic solutions. product created optimized meet specific requirements our clients. addition, adhering flexibility, company accommodate requests customization works provide magnetic assemblies exactly match customer specifications.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd