-

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Find out why a CNC magnetic chuck is beneficial

Looking for a safe and effective way to hold your metal parts in place while working? Enter the CNC magnetic chuck... versatile and useful! It has been widely known and used thanks to the many benefits it offers, including increased productivity;greater accuracy in splicing material from film rolls;and easier handling while working. Here, in this post of useful information we will help you to deeply understand the great number benefits and applications that those CNC magnetic chucks could cover as possible as they can prior enhance the safety usage and quality of them through a technical scrutiny which do provide exceptional services.

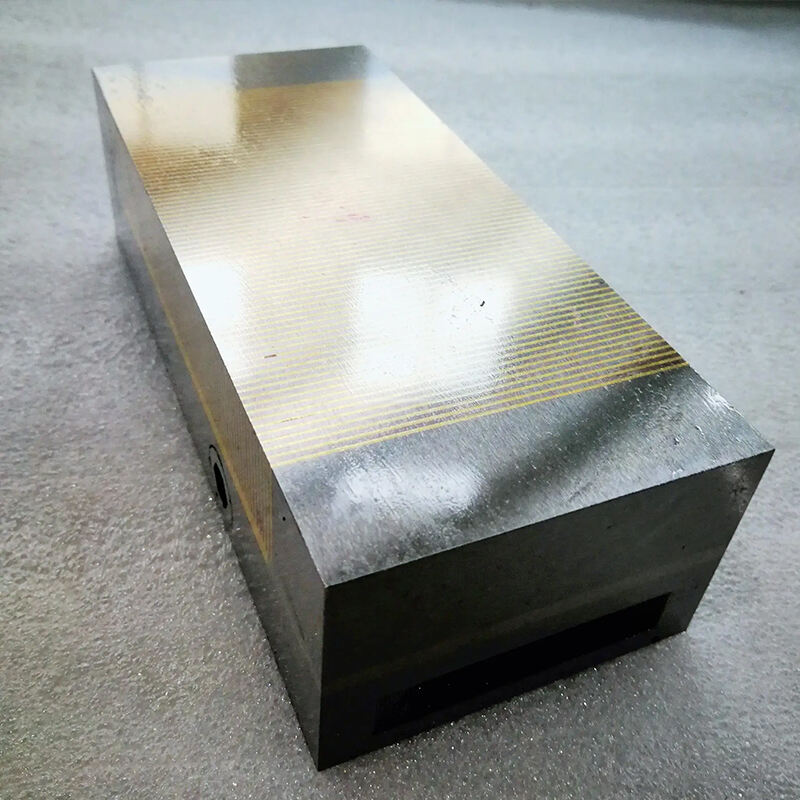

What is a CNC Magnetic Chuck with English Explanation?CNC magnetic chucks are designed to hold metal workpieces during the machining process securely. This is very beneficial because it allows the CNC magnetic chuck to offer a large holding force that prevents workpiece from moving or sliding during operation. As a result, the accuracy and precision becomes higher which helps in building to get to desired part finishes & fits. Closely-related to the issue of non-flatness is tool selection and accounting for workpiece size, as CNC magnetic chucks can hold a variety of flat or thin parts with little difficulty.

The most important feature among the features of CNC magnetic chucks also, it reduces set-up and changeover times that adds something to productivity. The workpieces are quickly clamped into and out of the pallets by their powerful holding force without tools or further fixtures. This simplifies initial setup efforts which means you can spend more time on other tasks that matter most, resulting in a higher production efficiency.

We prepare our CNC magnetic chucks with modern features that increase their accuracy and suitability. Made from premium, long-lasting materials that stand up to usual wear and tear these chuck are built last. In addition, they are built for high speed movement continuously applying a force at the same level to ensure your workpieces move smoothly and accurately.

Not to mention that our CNC magnetic chucks also come with an auto-demagnetization system, thus there would be no need for manual demagnetization. This reduces downtime and improves safety: no more need to enter the magnetic field what would otherwise lead to a potential hazardous situation. Also our chucks are very small and light to be easily managed & stored.

It is always our number 1 priority to make sure everyone is safe. Our CNC Magnetic Chucks are precision-designed to meet safety requirements and adhere to regulations in the segment. These chucks have safety measures such as a protective cover which is used to protect the magnetic field, protecting against accidents and ensuring protection of workpiecesillosion.

Safe Operation of CNC Magnetic Chuck Workpieces must be free of moisture and other debris as this may disrupt the magnetic force. However, one must never get close to the magnetic field either by hands or any other body parts and always keep away metallic objects from chuck area so that they will not stick accidentally.

A CNC magnetic chuck is easy to use. When you begin, make that both the workpiece surface and magnetic face of chuck are cleaned properly. Next, you must set your workpiece upon the chuck and press down hard on it to make sure that there is a tight grip. This way the workpiece is held in place with no margin for error whatsoever because of a strong magnetic force, allowing accurate machining.

To remove the workpiece, switch off the magnetic chuck and lift it from the surface. Especially for hot and sharp workpieces, a careful handling of the part is essential in order not to run into trouble!

Magland adheres rigorous quality controls throughout step manufacturing process. cnc magnetic chuck material screening final inspection product. product subject rigorous testing, making sure they satisfy technical well environmental requirements clients.

Magland puts premium technological innovation works cnc magnetic chuck academic research institutions stay top developments magnetism. ensures innovative magnet assemblies created meet unique needs customers.

Magland provides tailored solutions based on cnc magnetic chuck circuit simulation software. Magland specialist custom magnetic solutions. product created optimized meet particular requirements our clients. company flexible accepts special requests. strives create magnetic assemblies precisely line specifications customer.

Magland massive workshop covers cnc magnetic chuck square meters cnc magnetic chuck more 300 pieces top-of-the-line processing equipment including robotics automated machines. infrastructure enables precise efficient manufacturing procedures, ensuring top quality products.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd