-

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

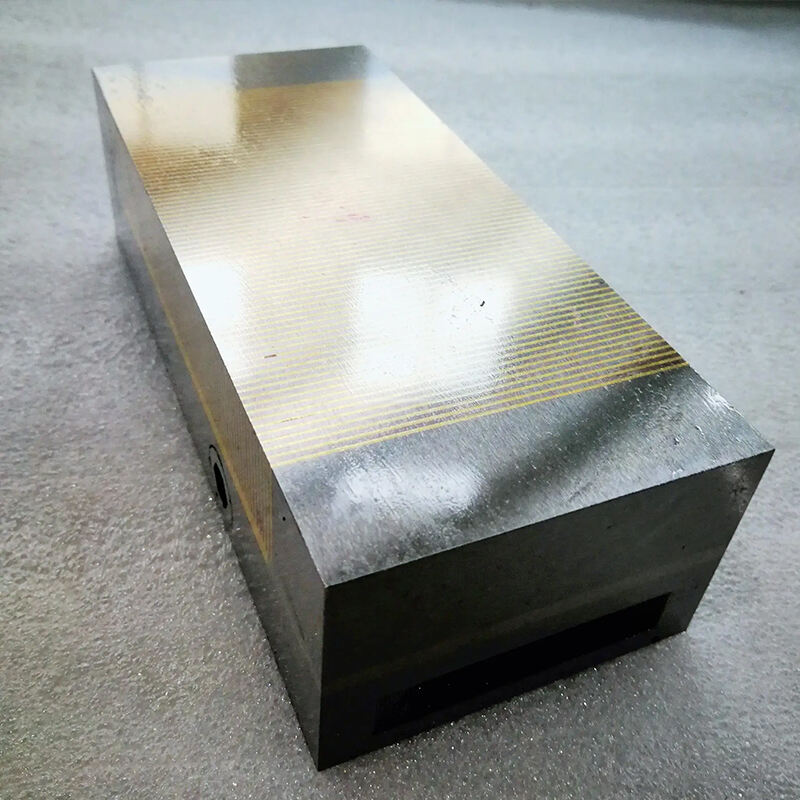

Magnetic Chucks - A Useful Part For Holding Workpieces In Place Correctly

Of all the fixtures, one of the most important tools in machining is a magnetic chuck as it assists in securing workpieces during operations. This quality of it from which parts can never get loose while you are bending or for example removing the device, is what makes lock-out equipment so precious in today's industrial manufacturing process. Magnetic Chucks - A Fascinating WorldIn this blog post, we intend to indulge ourselves in the magical world of magnetic chucks.

This includes the fact that a magnetic chuck has fantastic holding power - which results in workpieces not moving as they are machined. Not only that, but it makes work safer by removing the hazards of conventional clamping. And the last secret: you guessed it, ease of use - magnetic chucks killing setup time is one of many reasons they are so popular at the contemporary machining facilities.

Because of its multi-use approach magnetic chucks can be used with materials such as steel, cast iron and non-ferrous metals. Current advances in magnetic tech have made rare earth magnets, which produce a significantly higher holding power due to increased strength of the field. The invention of the magnetic chuck has been ground-breaking thus far in machining until its successor came along that steered a radical improvement of accuracy down to precision over time.

Safety Measures Taken with Magnetic Work-Holders:

Magnetic chucks are generally safe the use of, however usage is managed in an effort to avoid tragic accidents. To reduce the risk, operators are required to follow a number of safety guidelines including refraining from maintaining their body in magnetic fields for extended periods and workpieces must be securely fixed. It is necessary to carry out periodic maintenance and inspection of magnetic chucks in order to verify their correct functionality, assuring a safe production environment.

Magnetic chucks find a range of applications due to their versatile nature; they are used in lathes, grinders and milling machines. They are especially popular for holding shafts, rings and discs that cylinders may be workpieces with round magnetic chuck. Their inability to clamp on parts that are unsuitable for clamps or vices, including delicate materials and components of irregular shapes makes them a necessity in many machining scenarios.

Using Magnetic Chucks (Step-by-Step Walking Through)

A round magnetic chuck is simple to use and can be accomplished with a few easy steps. Just drop this chuck onto the machine table and make sure there are no dust or oil on it. Attach the chuck to a power supply according the manufacturer instructions, place work on it and switch that magnetic ON. Now that you have the workpiece installed securely, the machining process can begin with trust and accuracy.

The key factor when buying a magnetic chuck is the service and quality. Always buy from a manufacturer who provides customer support and offers quality products which will last for years to come. A maintenance and calibration service is provided by certain manufacturers to the customers, which highlights how important this process is in maintaining a longer lifespan for a Magnetic Chuck as well its maximum performance.

Magland strong focus development technology, cooperates research academic institutions remain forefront innovation round magnetic chuck. commitment ensures creation most cutting-edge magnetic assemblies, tailored meet clients' unique needs.

Magland provides tailored solutions based on round magnetic chuck circuit simulation software. Magland specialist custom magnetic solutions. product created optimized meet particular requirements our clients. company flexible accepts special requests. strives create magnetic assemblies precisely line specifications customer.

Magland extensive workshops cover 4000 square meters. equipped 300 pieces high-end processing equipment, which includes robots automated machinery. system allows precise efficient production round magnetic chuck assure superior quality product.

Magland adheres strict quality control throughout entire production process. initial screening raw materials through final product inspection. product subjected extensive testing, ensuring they meet round magnetic chuck well environmental requirements clients.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd