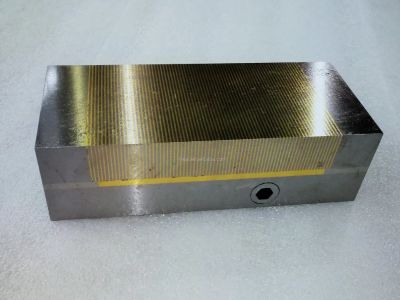

An extremely important and practical tool, magnetic chucks assist you to retain the metal items you are working on. They are particularly useful when machining, which is the process of shaping or cutting metal to form various components. But Melvin said that magnetic chucks are a bit tricky to work with sometimes. Mistakes are common when using them, and you need to know how to avoid and correct them. This allows you to have your projects up and running smoothly and securely at all times. Here at MagLand, we are here to help you make the most of your use of your magnetic chucks. So here are a few tips not to forget while working with them.

Tip # 1: Maintain cleanliness of the Magnetic Chuck

Keep Them Clean: One of the best tips concerning magnetic chucks is that they must be clean. Chucks are either made of wood or metal, and if there’s any debris, dust or metal scrap on the chuck surface, it will reduce the magnetic attraction force holding your metal piece. It can lead to an accident or a wrong doing on your work. However it is wise to ensure that you clean your magnetic chuck before use using a cloth or a rag. Often you can also blow the dust and debris with the help of compressed air supply if possible. For this chuck to operate as it should and to have your workpiece secured firmly then ensure that it is as clean as possible.

Avoid Losing Grip:

Magnetic chucks can also eventually lose their grip if there is too much debris buildup over the permanence of the chuck — leading to one of the other widespread problems that can come with magnetic chucks. This can happen for instance if the magnets are demagnetized or very old. When that does occur, the chuck will not hold your work piece well, which is quite annoying. In order to avoid that make sure you keep your magnetic chuck for milling somewhere that is safe and sound. Do not place it next to a strong magnet or magnetic field otherwise its performance will be affected. In addition, do not strike or drop your permanent magnetic chuck. There are powerful magnets inside, so dropping it or banging it can ruin it.

Prevent Rust:

Rusting can also be a factor with magnetic chucks, which require some care. When the chuck rusts over, it can take away the strength of the chuck, and that can make it less reliable. Always dry your magnetic chuck well if it gets wet when using it or when cleaning it. This will prevent rust formation. Another option is to spray rust inhibitor on it that keeps moisture from causing the chuck deteriorate. Using your magnetic chuck from time to time is an additional way to make sure that it does not get rusty and remains strong. Using it regularly helps maintain the magnetic power for holding metal pieces in place.

Ground Your Workpiece:

Of all the many things that you need to get right about magnetic chucks, one of them is to make sure that your metal piece is well – grounded. Working at good grounding ensures that you have a firm magnetic grip because this eliminate the chances of an accident or damaging your workpiece in the process. Earthing, you can earthing your workpiece whenever you make a connection through a wire from the work-piece to an earth point in your machine or workbench. This is why it enables your magnet to perform well and retain all to order while you are busy.

Check for Damage:

Last, but not least, perform a thorough check of your magnetic chuck in terms of crackling and wearing-out. If you have any problem with the chuck then it might be required to replace it. Well, it is rather simple, a damaged magnetic chuck not only contributes to an accident, but it also does not secure the workpiece property. That is why if your magnetic chuck is damaged, then you should ensure that it is disposed off in the most correct and safe manner. Maintenance of all used tools is crucial so that you provide for a safe usage and the correct manner.

EN

EN

AR

AR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SK

SK

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

GA

GA

XH

XH