-

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

Floor 1-2, Building 4, No.1628 Lizheng Road, Lingang New Zone, Shanghai

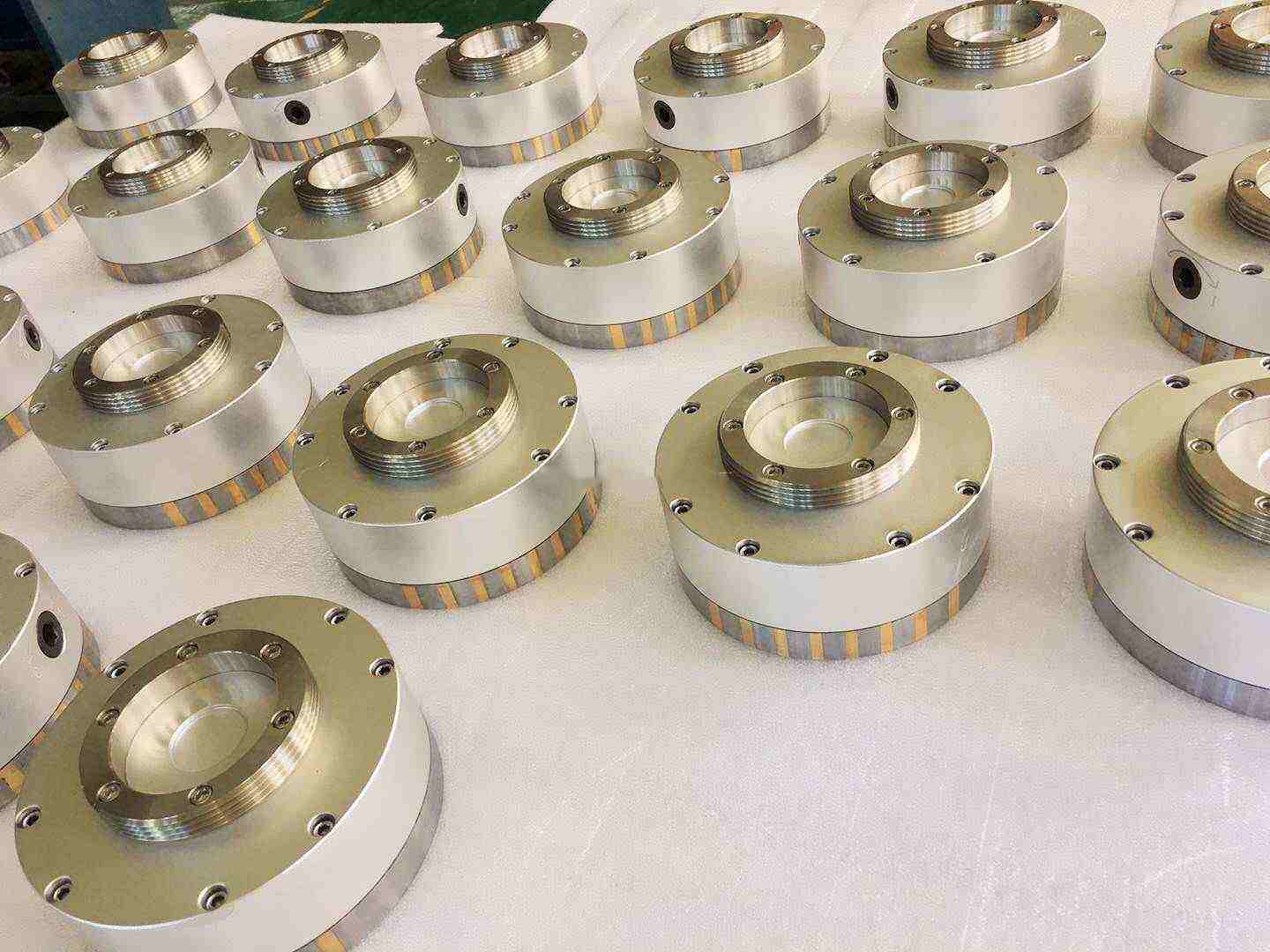

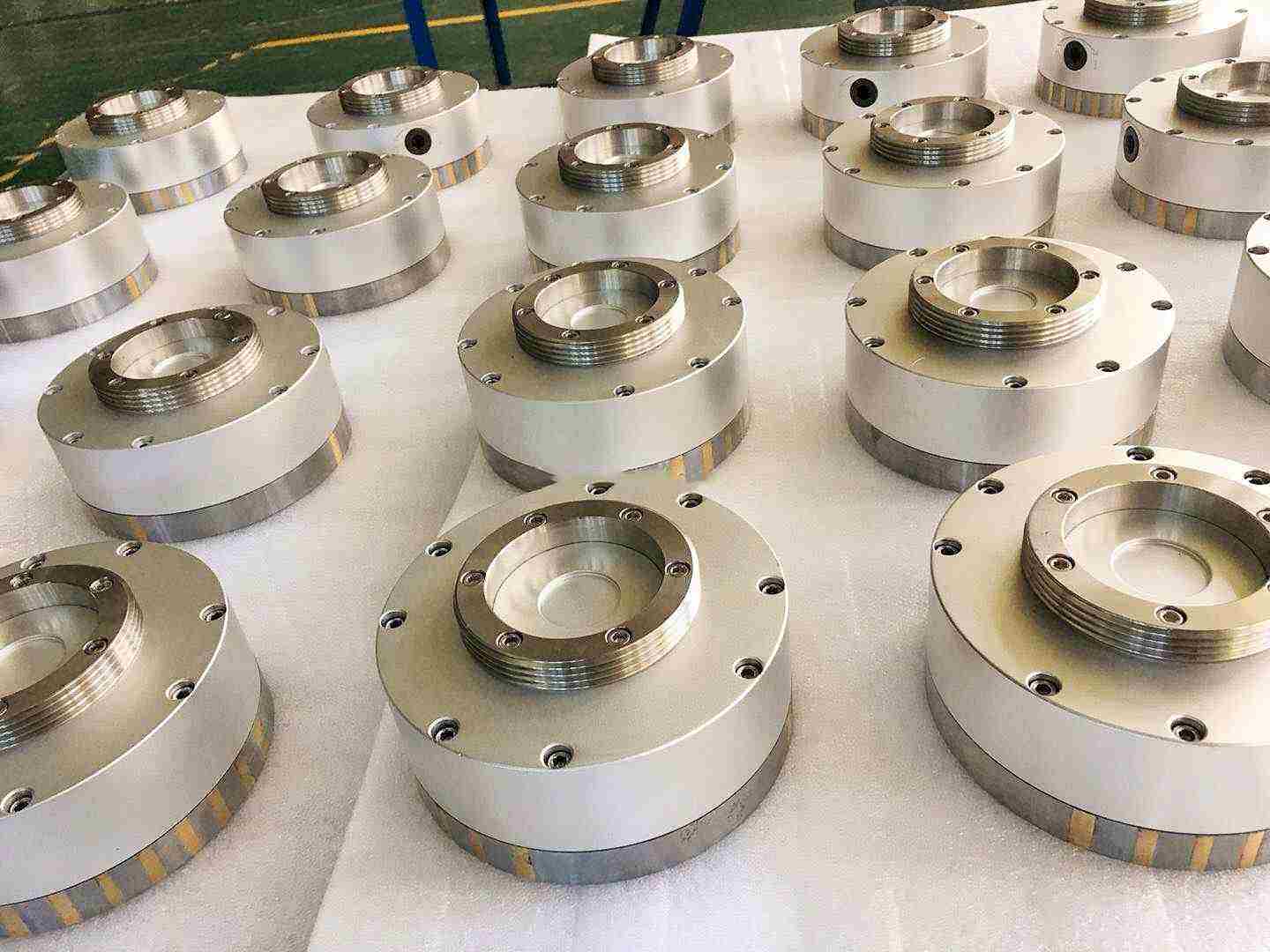

| Product Name | Dia.150 mm Permanent Magnetic Chuck For Grinding Machine | |||

| Material | Copper, Steel, NdFeB magnet | |||

| Size | 150 mm | |||

| Pole distance | 1+3 mm | |||

| Suction | 100-120N/cm2 | |||

| Application | For surface grinder, tool grinder, EDM and other applications. | |||

*We can also design according to your requirements if the specific size is not available on our website or catalogue.

Put the work piece on the suction table, and then insert the wrench into the shaft hole to turn clockwise 180°, the work piece can be sucked for processing.

The work piece is completed, the wrench can be inserted into the shaft hole to turn counterclockwise 180°, you can remove the work piece.

Features:

1. Sealed against dirt and liquid.

2.Removable handle.

3. Handle moves easily to turn chuck on and off.

4. Use powerful Rare Earth Neodymium Magnets inside.

5.Very fine spacing, uniform magnetic distribution, particularly for processing small thin parts.

6.Worktable precision no change while magnetizing and demagnetizing.

The magentic chuck can be uesed for processing various magnetic conduction work pieces.

For surface grinder, tool grinder, EDM and other applications.

Thin and light weight work piece are ideally suitable because of fine-pitched magnetic poles.

Maintenance:

1.Use of ambient temperature: -40℃-50℃.

2. Itshould be wiped clean before use to avoid scratching the surface, after using, the surface should be coated with oil to prevent corrosion.

3. Do not knock, to prevent magnetic reduction.

We are a manufacturer,our factory covers an area of 40,000 square meters. We own 120 employees including 11 technicists and 8 QC. We are a new factory founded in Year 2014, but our team focus on the magnetic technology over 20 years. And also our company is a National high-tech enterprise which own 10 patents for invention.

Copyright © 2024 Shanghai Magland Magnetics Co., Ltd